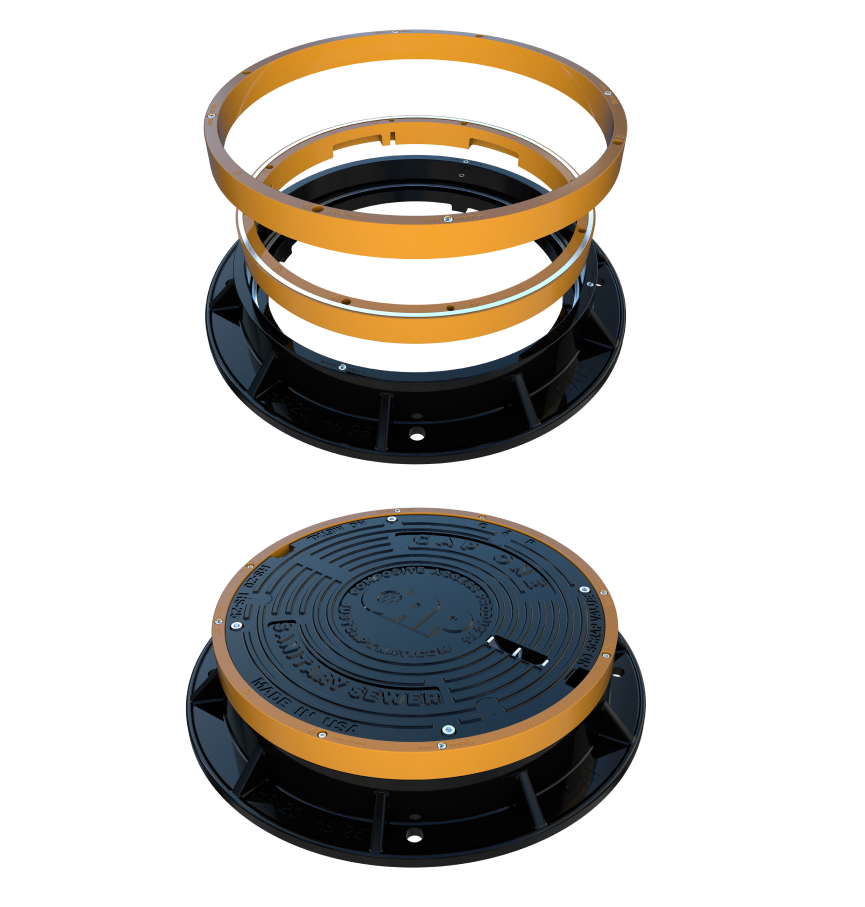

Another Groundbreaking Innovation from CAP™

Composite Access Products (CAP™) is a leader in creating innovative infrastructure solutions, known for durable and reliable composite manhole covers. With the new Halo™ top riser ring system, CAP™ brings the same advantages of their manhole covers to a new problem in road maintenance. The Halo™ makes it easier to raise manhole covers during repaving, adding value to CAP™’s products for the future.h